IntWaste

Within the framework of the Applied Research and Innovation framework, since 2020 ElvalHalcor’s copper and alloy extrusion division, in collaboration with the University of Patras, has implemented the IntWaste Circular Economy project as part of the National “RESEARCH – CREATE INNOVATE” program, co-financed by the European Union’s European Union Regional Development Fund (ERDF) and national resources through the Competitiveness, Entrepreneurship & Innovation Program.

Started at: 16/06/2020

Ended at: 16/08/2023

Objectives:

- Installation of the necessary equipment to maximize waste collection capacity (specifically for copper and plastics) at each Work Center.

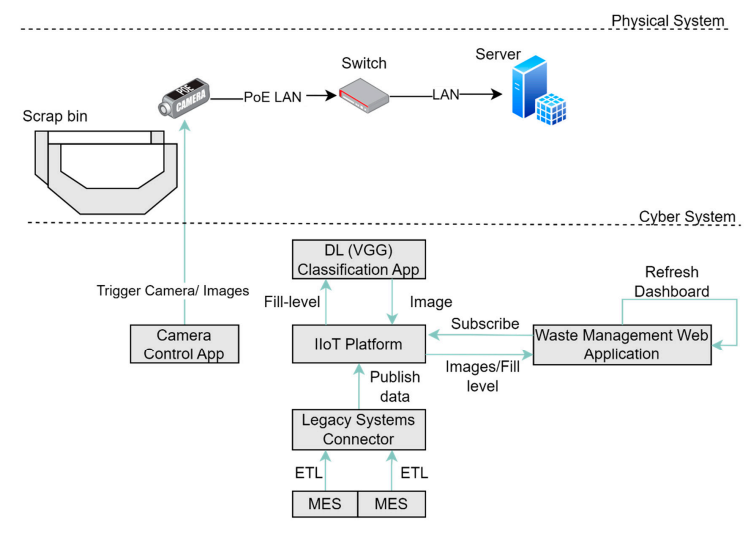

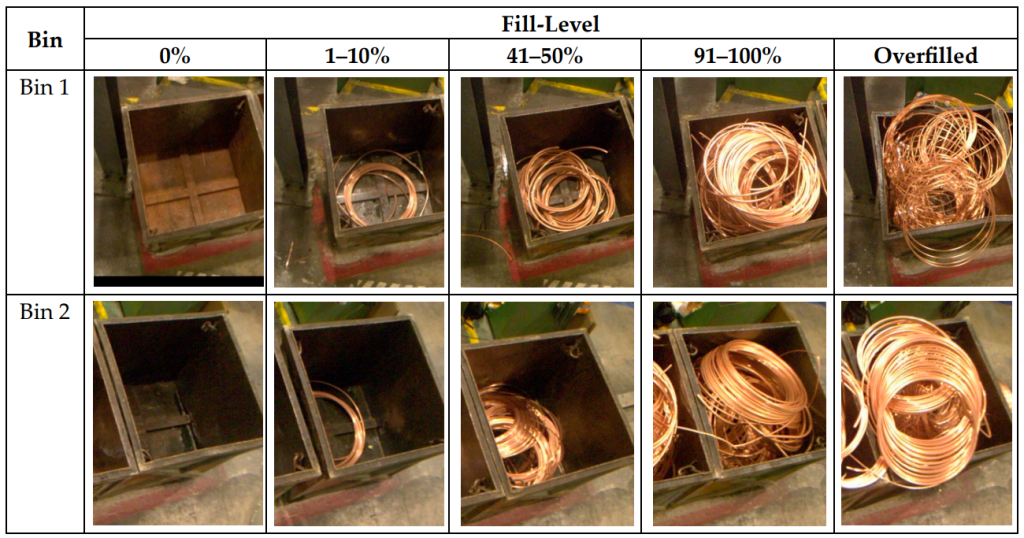

- Installation of equipment for monitoring and managing waste bins and other collection equipment

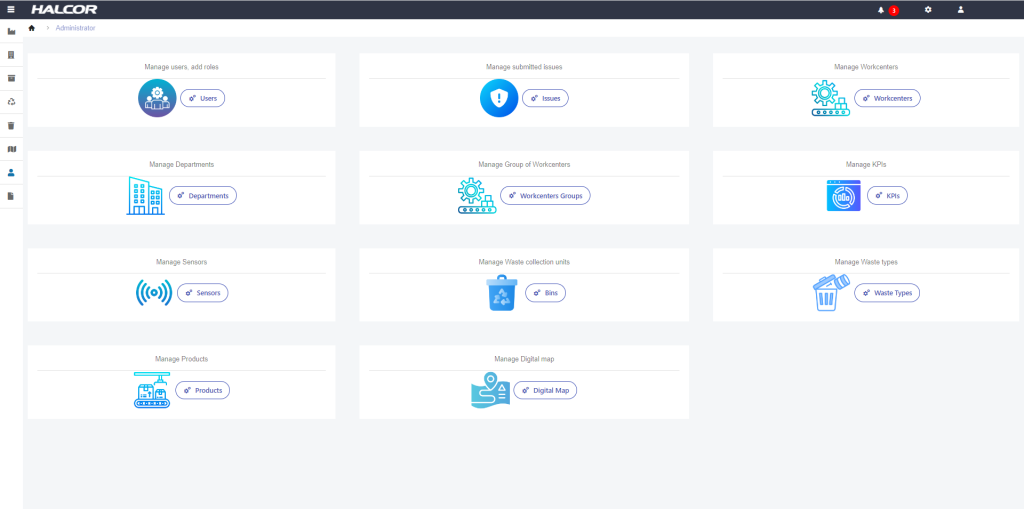

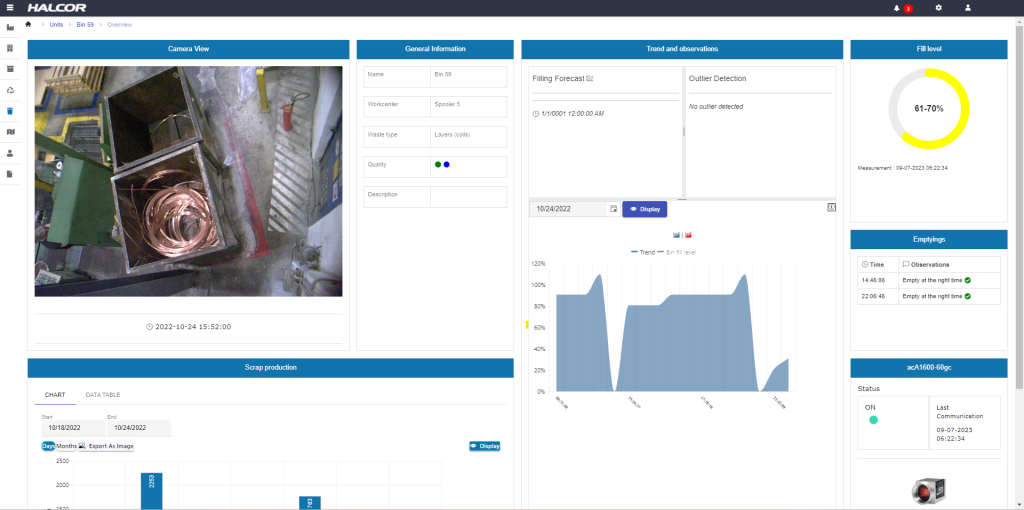

- Development of a waste management platform that includes roles for Waste Managers and Waste Producers, along with the installation of the required infrastructure.

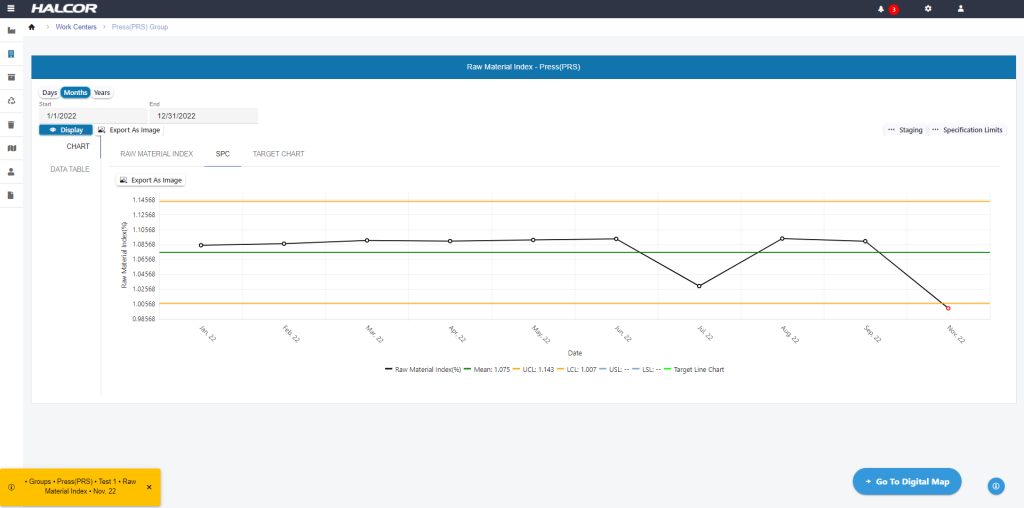

- Creation of specifications, including upper and lower control limits, for the expected standard waste collection rates and the anticipated rate of filling collection bins for different types of waste. These specifications will be linked to machine operating hours and production menus for each Work Center and will be obtained from the Electronic Execution System and Production Control (MES – Manufacturing Execution System).

- Real-time monitoring of the fill levels in collection bins, comparing them to the established specifications. Prompt alerts for investigating deviations and defining corrective actions.

- Displaying the factory map in an electronic format to facilitate waste tracking and management.

Innovative circular economy – IntWaste project concerns the evolution of the circular economy project at Halcor’s Copper Tubes Plant. Working steadily towards implementing a circular economy, Halcor has designed a smart Waste Management System seeking optimal solutions for a Sustainable and Green Economy. The IntWaste project lays the foundations for Industry to transition to more cyclical models of production and consumption as well as to a Sustainable Digital Future. Through the development of an IoT platform, IntWaste aims at intelligent real-time waste tracking, ultimately reducing waste generation and wasting resources, using intelligent systems and sensors. The first phase of the project saw the completion of the design of the monitoring platform. A Circular Model was designed according to innovative and modern methodologies (Ellen McArthur), customized to the needs of the production process of Halcor’s Copper Tubes Plant. Significant strides have been made in the implementation of our Industrial Internet of Things (IIoT) platform and its integration with our existing industrial systems. This foundational work has laid a strong groundwork for our project and for future work. Concurrently, significant headway has been made in the deployment of sensors and intelligent systems within Halcor’s production processes, utilizing state-of-the-art Neural Networks and Deep Learning algorithms (as part of pilot/research initiatives). The primary aim here is to enhance our ability to monitor and reduce copper/plastic waste, proactively preventing incidents. As we navigate this project, we adhere to the Lean Six Sigma methodology, ensuring a data-driven approach to process improvement. Furthermore, we’ve successfully achieved the first step towards data visualization by creating a user-friendly platform.

Platform Images: